Flake Epoxy Flooring Bribie Island & Sandstone Point

Seamless hard wearing concrete coatings system perfect for garage floors, patio’s, paths, driveways and commercial floors.

- Moreton Bay

- Brisbane North

- Somerset Region

Looking For Experienced Installers For Flake Epoxy Flooring Bribie Island & Sandstone Point?

Durable flake epoxy flooring Bribie Island that will provide you many years of trouble free use starts with the really important attention to detail for preparing all concrete floors. Ultimate Floors are specialist with both indoor and outdoor concrete renovation finishes for a fantastic way to enhance your street appeal and value add to your property. Additionally, businesses of all types can gain a great looking flake epoxy floor that is extremely durable.

Flake epoxy flooring is a seamless finish that is water resistant and an ideal option for external concrete. As a result of this, Ultimate Floors has options for you to customise your flake epoxy flooring Bribie Island and Sandstone Point is what sets us apart from the general flake floor finishers.

If you are looking for a new floor finish that can be customised to suit your requirements, get in touch with Ultimate floors flake epoxy flooring Bribie Island and Sandstone Point installation services to find out more about your options. Your brand new floor is tough, long lasting and can be a smooth finish or non-slip option. Additionally, further personal touches such as a different base coat colour or have us add glow in the dark flakes for cool effects.

- UV resistant perfect for driveway flake epoxy

- Garage flake epoxy flooring installations

- Non-slip and great chemical resistance pool area flake epoxy

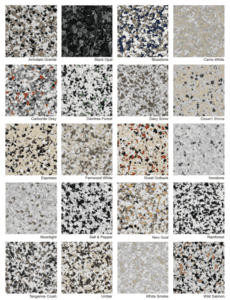

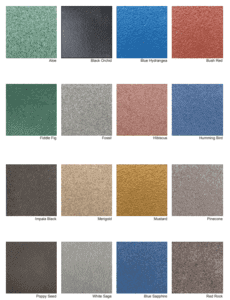

- 100 + Colour combinations - Small Flake, Large Flake, Stone Look, Glow In The Dark Flake

- Excellent choice for day care centres and schools - Low VOC, no out gassing, 100% safe

Preparing The Floor

Correctly preparing the flake epoxy floor or external concrete surface is really important. Unless it is 100% contaminant free, is sound with no surface dusting problems, the floor is not fully prepared and ready for garage flake epoxy flooring Bribie Island?

Furthermore, the use of acid as a the preparation is a failure awaiting to happen. Hiring a professional floor grinder with HEPA silica dust control and testing equipment are required for DIY epoxy flake flooring.

If you feel you have the technical know how and you are componant with what can go wrong, fabulous. All we say is this, it costs more to get it right the second time round and really not an economical approach.

Your Flake Epoxy Floor Options

Flake epoxy flooring is a combination of resin coatings to adhere and secure small acrylic floor flake chips cast in. Ultimate Floors use various flooring resins for different situations.

For example, 100% solids epoxy emits low odours at the time of application. Hardening time is dependent on air / surface temperatures and epoxy floor coating thickness.

With choices for fast curing floor resins and a broader range of epoxy flake floor colours, our installations aren’t based on a square metre cost, the process is specific to your area of use.

Decorative flake epoxy flooring Bribie Island is highly desirable for those who require an extremely durable surface to withstand the abrasion of sand for a flake floor living area or flake epoxy driveway finish.

Why DIY flake epoxy floor can be a costly

Epoxy floor coating tends to have a DIY appeal for what may appear to be a quick and easy finish. It is common to see cheap garage floor epoxy last a year or two. A few reasons why DIY epoxy coatings fail.

- Incorrectly preparing the surface is the number one reason of failures.

- Low quality resins generally suffer from peeling from hot tyre heat transfer.

- QA Checks for alkalinity and moisture

Choosing Ultimate Floors attention to detail epoxy floor coating Bribie Island ensures the floor resin stays well bonded for long term performance.

Using acid as a the preparation is a failure waiting to happen for many reasons. Australian Standards and resin flooring manufactures simply don’t recommend acid etch clean as suitable preparation. For this reason, Ultimate Floors carries out diamond grinding or shot blasting for all epoxy flake flooring jobs across Bribie Island Qld.

- Checks for moisture and PH / alkalinity levels (Advise on remedial works as required)

- Repair / patch divots and cracks

- Floor Preparation

- Moisture barrier or crack bridging polyurea as per site requirements

- Clear or coloured primer coat where #4 above is not required

- Base Colour plus Flake Chip

- Clear away excess broad cast flake, vacuum

- Clear Polyurethane Top Coats (1 coat option to save on initial installation) 2 clear coats is recommended, we can discuss with you in more detail where required

- Flake epoxy flooring installation can be customised to suit a smooth living area floor or non-slip outdoor concrete finish

Ready To Talk?

Australian Suppliers and Manufactures

Driveways – Patios – Pool surrounds

Entries – Offices – Cafes – Living Areas

Latest Chemistry – Low Odours – Low VOC